- HOME

- > Measuring Instrument Products Top

- > Zirconia Type Gas Oxygen Analyzers (O2 Meters)

- > TF-II, TF-III, TF-IV

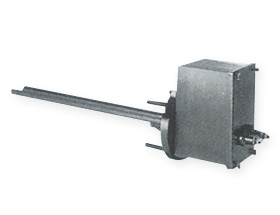

TF-II

Transmitter Model TF-II

Receiver Model TF-IIM

- Flame-proof structure certified by passing the type test

- Applicable to combustion exhaust gas under extreme conditions, such as high-temperature exhaust gas and exhaust gas from boilers

- No need of standards gas or reference air (air 1-point calibration)

Use

- Combustion control for industrial heating furnaces for petroleum refinery, petrochemistry and city gas making

- Combustion control of atmosphere gas

Specifications

| Model | Transmitter Model TF-II |

|---|---|

| Explosion-proof structure | d2G4 type test pass No. 44241 |

| Measurement principle | Zirconia 2-cell pump form |

| Material | Transmitter: SCS13 Probe: SUS310S/Inconel Flange: SUS304 |

| Weight | Transmitter: Approx. 11kg Probe: Approx. 10kg |

| Product | Receiver Model TF-IIM |

|---|---|

| Measurement range | 0 – 5/10/ 25vol% O2 For remote changeover range: Selection of 2 ranges out of these 3 ranges |

| Output | 4 – 20mADC Non-insulation, load resistance: ≦300Ω |

| Precision | Reproducibility: ≦±1.0%FS, Linearity: ≦±2.0%FS, Drift: ≦±2.0%FS/week (There should be one or more calibration points within the calibration range.) |

| Response time | ≦15 sec: 90% response at calibration gas changeover |

| Warming-up time | Approx. 3 min |

| Calibration | One-push manual calibration with span gas 1-point Calibration gas flow rate: 1 – 2L/min |

| Automatic diagnosis function | Receiver error, sensor error, calibration error |

| Contact output | 2 points: Open collector output (Receiver error, sensor error) 1-point for remote range changeover (Receiver error and sensor error: OR output) |

| Output value hold function | Holds output signal to 0% or last output value, whichever selected. |

| Explosion-proof grade | d2G4 type test pass No. 45930 |

| Utility | Power: 85 – 264VAC, 60/60Hz, Approx. 50W Steam: 0.1 – 0.4MPaG to be used for probe steam jacket |

TF-III

Transmitter Model TF-III

Receiver Model DTF-101

- Applicable to combustion exhaust gas under extreme conditions, such as high-temperature exhaust gas and exhaust gas from boilers

- No need of standards gas or reference air (air 1-point calibration)

Use

TF-III

- Combustion monitoring and control for heating furnaces, holding furnaces, air-heating furnaces

- Combustion monitoring and control of boilers

TF-IIIG

- Combustion monitoring and control for gas melting furnaces

Specifications

| Model | TF-III | TF-IIIG | ||

|---|---|---|---|---|

| (For boilers) | (For steel and iron) | |||

| Measurement principle | Zirconia 2-cell form | |||

| Sampling method | Direct-connection to furnace wall method / Ejector suction method | |||

| Measurement coverage | 0 – 5 / 0 – 10 / 0 – 25%O2 | |||

| Precision | Reproducibility | ±0.5%FS (0 – 10 / – 25% range), ±1%FS (0 – 5% range) | ||

| Linearity | ± 1%FS (0 – 10 / – 25% range), ±2%FS (0 – 5% range) | |||

| Output | 4 – 20mADC, 1 – 5VDC Non-insulated output, load resistance, voltage output: ≧10kΩ, current output: ≦600Ω |

|||

| Response time | 10 sec (90% response at calibration gas changeover) | |||

| Calibration | Automatic (1-point/1-range calibration by air) | |||

| Warming-up time | Sensor: 3 min, Heater: 30 min | |||

| Power source | 100VAC±10%, 50/60Hz, 300VA | 100VAC±10%, 50/60Hz, 500VA | ||

| Air source | Equivalent to instrumentation air Pressure: 0.4 – 0.7MPaG 1L/min at calibration 3 - 12L/min when ejector air is used |

Equivalent to instrumentation air Pressure: 0.4 – 0.7MPaG 1L/min at calibration 10 – 20L/min at purge 3 - 12L/min when ejector air is used |

||

| Measurement gas conditions * |

Temperature | ≦700°C | ≦1,350°C | ≦1,500°C |

| Dust content | ≦100mg/Nm3 | ≦500mg/Nm3 | ||

| Flow rate | 0 – 20m/sec | 0 – 10m/sec | ||

| Pressure | ±5kPa | |||

| H2O | ≦20% | |||

| SOx | ≦2,000ppm | |||

| NOx | ≦500ppm | |||

| Others | No special gas | |||

| External dimensions | Transmitter unit | 155(W)×200(H)×265(D) Excluding projection |

155(W)×200(H)×350(D) Excluding projection |

|

| Receiver unit | 400(W)×700(H)×260(D) | |||

| Mounting flange | JIS5K65AFF | |||

| Transmitter mounting direction | Horizontal or vertically downward | Horizontal (up to 5°downward) | ||

| Weight | Transmitter unit: 4kg, Probe (L = 1,000mm): 2.2kg | |||

* For other conditions , consult with us.

TF-IV

Transmitter Model TF-IV

Receiver Model DTF-101

- Applicable to combustion exhaust gas under extreme conditions, such as high-temperature exhaust gas and exhaust gas from boilers

- No need of standards gas or reference air (air 1-point calibration)

Use

- Monitoring and control of combustion at refuse and sludge incinerator outlets

- Monitoring and control of combustion at melting furnace outlets

Specifications

| Model | TF-IV | |

|---|---|---|

| Measurement principle | Zirconia 2-cell form | |

| Sampling method | Direct-connection to furnace wall method / Differential pressure suction method | |

| Measurement range | 0 – 10 / 0 – 25%O2 | |

| Precision | Linearity | Within ±1% |

| Reproducibility | Within ±0.5% | |

| Output | 4 – 20mA, Isolate output, Load resistance: ≦500Ω | |

| Response time | 10 sec (90% response at calibration gas changeover) | |

| Calibration | 1-point automatic calibration by air | |

| Probe purge | Automatic purge (with indicated hold) | |

| Warming-up time | Sensor: 3 min, Heater: 30 min | |

| Power source | 100VAC±10%, 50/60Hz, 500VA | |

| Air source | Equivalent to instrumentation air Pressure: 0.4 – 0.7MPaG 3L/min at calibration 0.5Nm3/min at purge |

|

| Measurement gas conditions* | Temperature | ≦900°C |

| Dust content | ≦30mg/Nm3 | |

| Flow rate | 5 – 20m/sec | |

| Pressure | ±5kPa | |

| H2O | ≦40% (No oversaturation) | |

| SOx | ≦400ppm | |

| NOx | ≦500ppm | |

| HCl | ≦1,000ppm | |

External dimensions |

Transmitter unit | 188(W)×207(H)×165(D) Excluding projection |

| Mounting flange | JIS10K65AFF | |

| Transmitter mounting direction | Horizontal or vertically downward | |

| Weight | Transmitter unit: 8.3kg, Probe (L = 1,000mm): 2.4kg | |

* For other conditions , consult with us.

- HOME

- > Measuring Instrument Products Top

- > Zirconia Type Gas Oxygen Analyzers (O2 Meters)

- > TF-II, TF-III, TF-IV